Auxiliary Machines and Their Role in Modern Manufacturing

In modern manufacturing, auxiliary machines play a crucial role, especially in plastic processing. These devices not only improve production efficiency but also ensure product quality stability and precision. Ningbo Zhenfei Injection Molding Machine Manufacturing Co., Ltd., as a leading company specializing in injection molding machine R&D, production, and sales, fully understands the importance of auxiliary machines in the manufacturing process. In today’s manufacturing environment, how to enhance production efficiency and product quality through efficient auxiliary machines is a challenge every manufacturer must address.

Auxiliary machines typically support the main production equipment and include, but are not limited to, material conveying systems, drying equipment, cooling systems, temperature control devices, etc. These machines help maintain continuity, stability, and efficiency in production while reducing human intervention and lowering the rate of production errors. For companies like Ningbo Zhenfei, optimizing auxiliary machines can significantly improve the performance of injection molding machines, ultimately enhancing customer satisfaction and market competitiveness.

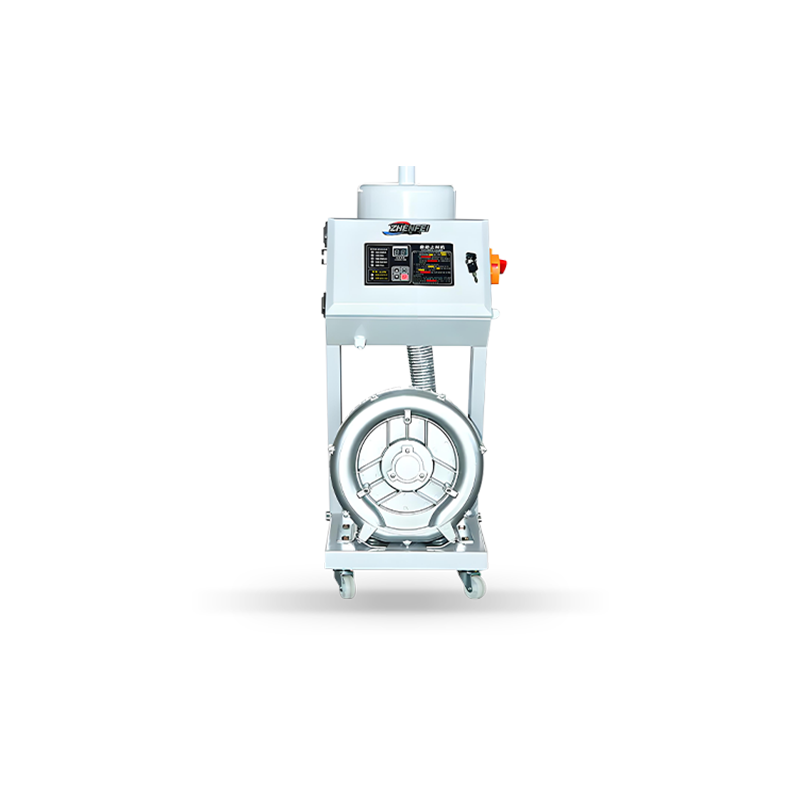

For example, plastic dryers play a key role in plastic processing, especially before injection and extrusion, as they effectively remove moisture from plastic raw materials. Excess moisture in plastics can lead to defects such as bubbles, cracks, or color discrepancies during molding, directly affecting the quality and appearance of the product. By introducing advanced drying technology and equipment, Ningbo Zhenfei ensures that every injection molding machine operates smoothly, reducing quality fluctuations and downtime during production.

Additionally, the material conveying system is an indispensable part of auxiliary machinery. It accurately transports raw materials to the injection molding machine, minimizing human error and ensuring smooth production flow. For manufacturers producing precision products, the efficiency of the conveying system directly impacts the overall efficiency of the production line. Thus, Ningbo Zhenfei focuses on integrating advanced auxiliary equipment into every injection molding machine design to improve overall production performance.

What Are Auxiliary Machines, and How Do They Improve Efficiency in the Production Process?

Auxiliary machines refer to those machines that support and optimize the production process in addition to the main production equipment. Their role mainly involves automating or optimizing various production stages to improve efficiency and product quality. For companies like Ningbo Zhenfei Injection Molding Machine Manufacturing Co., Ltd., the application of auxiliary machines is an essential part of ensuring that injection molding machines run efficiently and reliably.

In traditional production processes, efficiency improvement is often constrained by several factors such as complicated manual operations, frequent equipment failures, and improper material management. The introduction of auxiliary machines helps address these problems by automating and optimizing processes. For example, the automatic feeding system ensures that raw materials are delivered precisely to the injection molding machine, reducing raw material waste and maintaining production stability. Moreover, it minimizes manual errors, ensuring that the production process operates smoothly.

Drying equipment, temperature control machines, and other auxiliary devices play crucial roles in plastic processing. Plastic raw materials need to be dried before processing; excess moisture can adversely affect the plastic’s processing characteristics, resulting in defects. Ningbo Zhenfei’s injection molding machines are equipped with advanced temperature control systems to ensure precise control over machine temperatures, which is essential for improving product dimensional accuracy and appearance.

The cooling system also significantly contributes to plastic molding by efficiently dissipating heat, ensuring that the molded product maintains the correct dimensions and appearance. Inadequate cooling can result in deformed products or dimensional inaccuracies, which directly affect production efficiency and product quality. By integrating efficient cooling systems, Ningbo Zhenfei can maintain high-quality production while reducing cycle times.

By combining auxiliary machinery innovations with high-performance injection molding machines, Ningbo Zhenfei continuously enhances its machines’ competitiveness in the market, meeting customers’ demands for efficient, stable, and high-quality products. The efficient use of auxiliary machinery is key to enhancing competitiveness in modern manufacturing.

How Are Plastic Auxiliary Machines Different from Traditional Auxiliary Machines?

Plastic auxiliary machines are specifically designed to meet the unique needs of plastic processing. Compared to traditional auxiliary machines, plastic auxiliary machines not only provide basic support functions but also focus on precision operation in plastic production. Since plastic processing involves dealing with different types of plastic materials, each with varying flow properties and temperature sensitivities, plastic auxiliary machines must offer higher specialization and adaptability.

For example, the temperature control device plays a critical role in the injection molding process, directly influencing the final product’s quality. The flow properties and curing behavior of plastics are closely related to temperature. If the temperature control system cannot maintain precise temperature regulation, it can lead to product defects such as size discrepancies, weight issues, or visual flaws. Therefore, Ningbo Zhenfei integrates advanced temperature control systems in its injection molding machines to ensure that each batch of plastic products is molded under optimal conditions, preventing defects.

The automatic dosing system is another innovation in plastic auxiliary machinery. This system can automatically and precisely mix various raw materials according to the specific production needs, ensuring the stability of the plastic’s physical properties and chemical composition. In the injection molding process, strict control over the ratio of different types of plastics or additives is essential, as deviations can affect the strength, elasticity, and durability of the final product. Through high-precision dosing equipment, Ningbo Zhenfei offers highly customized production solutions that ensure every injection molding machine produces stable, high-quality plastic products.

In plastic processing, the design of cooling systems also differs significantly from traditional machinery. Since plastic products need to be rapidly cooled during molding to maintain their shape and accuracy, traditional cooling systems often cannot meet the high-efficiency demands. Therefore, Ningbo Zhenfei’s injection molding machines feature a unique cooling design, using efficient liquid circulation and temperature control technologies to rapidly and evenly dissipate heat, ensuring that plastic products reach the molding standard in the shortest time possible.

Plastic auxiliary machines, through more precise control and more efficient designs, can handle the complex challenges encountered in plastic processing, making the production process more efficient and stable, while enhancing the quality and consistency of plastic products.

Why Are Plastic Auxiliary Machines Crucial for Quality Control in the Production Process?

In modern plastic processing industries, quality control remains a core issue. Even the most advanced injection molding machines and extrusion machines can experience quality fluctuations if they lack precise auxiliary machinery. Ningbo Zhenfei Injection Molding Machine Manufacturing Co., Ltd. understands the importance of quality control in plastic processing, which is why we place great emphasis on the development and innovation of auxiliary machines to ensure every injection molding machine operates under high-quality control standards during production.

In plastic processing, quality fluctuations are often caused by instability in factors such as temperature, humidity, and material ratios. Any variation in these parameters can result in molding defects, dimensional inaccuracies, or poor physical properties. To mitigate these quality risks, Ningbo Zhenfei integrates auxiliary machines with injection molding machines to guarantee product consistency and precision.

For example, the temperature control system plays a vital role throughout the injection molding process. It not only regulates the mold temperature but also adjusts the plastic’s melt temperature during injection, preventing temperature fluctuations that can adversely affect product quality. Through Ningbo Zhenfei’s temperature control technology, injection molding machines maintain stable production conditions, ensuring each product batch meets dimensional and aesthetic requirements.

The automatic dosing system is also crucial for quality control. This system ensures the precise ratio of raw materials in each production cycle, preventing variations in the composition that could affect the final product’s quality. For high-end markets, where product quality standards are stringent, Ningbo Zhenfei ensures that every injection molding machine produces high-quality, standardized plastic products.

| Auxiliary Machine |

Function |

Impact on Quality Control |

| Material Feeding System |

Automatically feeds raw materials to the machine |

Minimizes waste and maintains material consistency |

| Drying System |

Removes moisture from plastic raw materials |

Prevents defects like bubbles, cracks, and discoloration |

| Temperature Control System |

Regulates mold and material temperature |

Ensures product dimensional accuracy and surface quality |

| Cooling System |

Rapidly cools molded products |

Prevents deformation and dimensional inconsistencies |

| Automatic Dosing System |

Precisely mixes raw materials |

Guarantees product consistency and material integrity |

中文简体

中文简体 English

English Español

Español

中文简体

中文简体