Date:Sep 22, 2025

Injection molding is a manufacturing method that melts plastic and injects it into a mold, then cools and solidifies it to produce parts. The core idea is to heat and plasticize solid pellets, drive the melt into a precisely machined cavity under high pressure, cool it until it solidifies, and eject the finished part.

Plastic pellets are supplied from a hopper into the barrel.

A rotating screw conveys the pellets forward while compressing and mixing them.

Heaters around the barrel and shear heat from screw rotation melt the pellets into a homogeneous molten state.

The molten plastic accumulates in front of the screw tip, preparing a measured shot for injection.

When the shot size is ready, the screw moves forward like a plunger, generating high pressure.

The melt passes through the nozzle and the mold's runner system (sprue, runners, and gates) into the cavity.

High pressure forces the melt to completely fill the cavity, even for thin walls and complex geometries, reducing voids and sink marks.

The mold contains cooling channels (commonly water-cooled) that remove heat from the plastic.

As temperature drops, molecular mobility decreases and the plastic solidifies into the mold shape.

Cooling time depends on resin properties, wall thickness, part geometry, and mold design, all of which affect cycle time and quality.

After sufficient cooling, the mold opens to release the parting line.

Ejector pins, sleeves, or a stripper plate push the part out of the cavity while protecting functional surfaces.

The mold closes and the next cycle begins, enabling repeatable, high-volume production.

Stores and feeds plastic pellets. It may include drying to prevent moisture from degrading part quality.

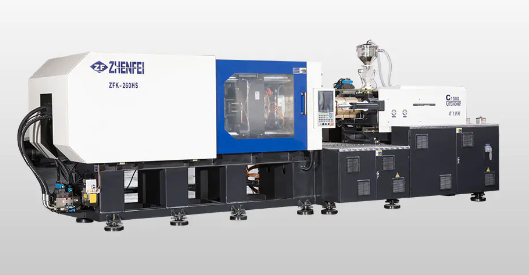

The barrel houses heaters to supply thermal energy, while the screw plasticizes, mixes, and conveys material and builds pressure.

Connects the barrel to the mold and directs the molten plastic into the runner system with minimal heat loss and leakage.

A precision tool comprising cavity and core that defines part geometry, surface finish, and dimensional accuracy.

Provides clamping force to keep the mold tightly closed during injection and packing, preventing flash.

Integrated cooling channels control mold temperature to speed solidification and stabilize dimensions.

Uses ejector pins, sleeves, or plates to push the solidified part out reliably without damage.