Plastic injection machinery works by melting plastic pellets or granules and injecting them into a mold to create a specific shape or part. The process involves several stages, including:

1.Melting: The plastic pellets or granules are melted in a hopper or cylinder using heat and pressure.

2.Injection: Once the plastic is melted, it is injected into a mold through a nozzle using a ram or screw, depending on the type of machinery.

3.Cooling: The plastic is cooled and solidified inside the mold to create a specific shape or part.

4.Ejection: The finished part is ejected from the mold, and the cycle starts again.

Plastic injection machinery is used in a wide range of industries and applications, including:

1.Automotive: Plastic injection machinery is used to create various parts for automobiles, including dashboards, bumpers, and interior trim.

2.Medical: Medical devices such as syringes, surgical instruments, and prosthetics are often made using plastic injection machinery.

3.Electronics: Plastic injection machinery is used to create parts for electronics such as phone cases, computer housings, and keyboards.

4.Packaging: Plastic injection machinery is used to create packaging for food and beverages, cosmetics, and other consumer products.

5.Toys: Many toys and games, including action figures, puzzles, and board games, are made using plastic injection machinery.

6.Household appliances: Plastic injection machinery is used to create parts for household appliances such as refrigerators, washing machines, and vacuum cleaners.

It works by melting plastic pellets or granules and injecting them into a mold to create a specific shape or part. Its applications are vast, including automotive, medical, electronics, packaging, toys, and household appliances. When selecting

Plastic Injection Machinery Manufacturing, it is important to consider the size and complexity of the parts you want to create, the type of plastic material, and the efficiency of the machinery to ensure that you choose the right machinery for your needs.

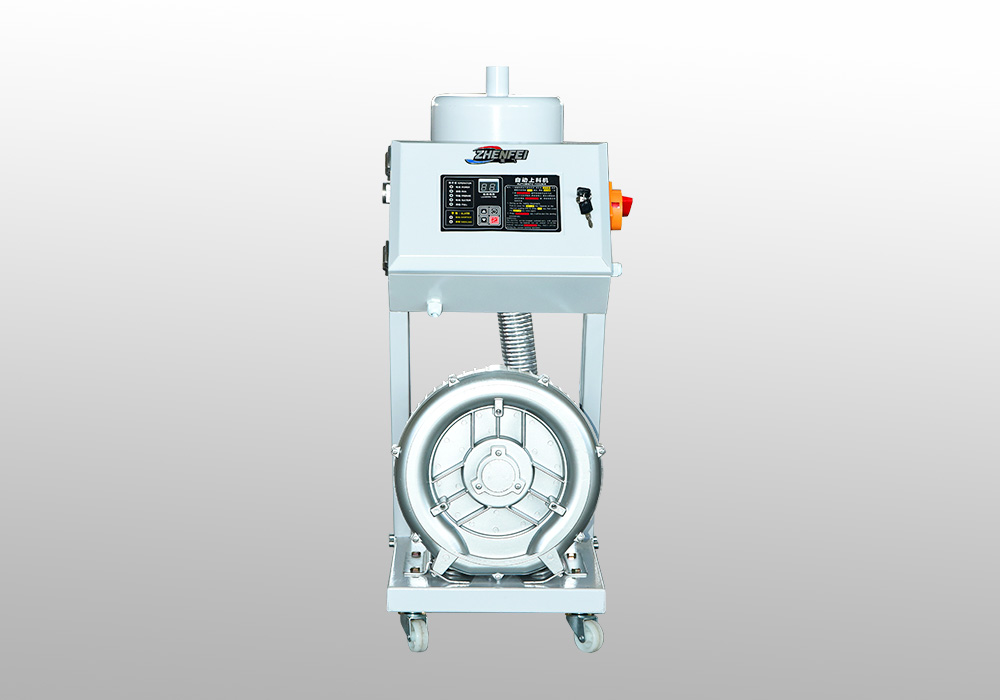

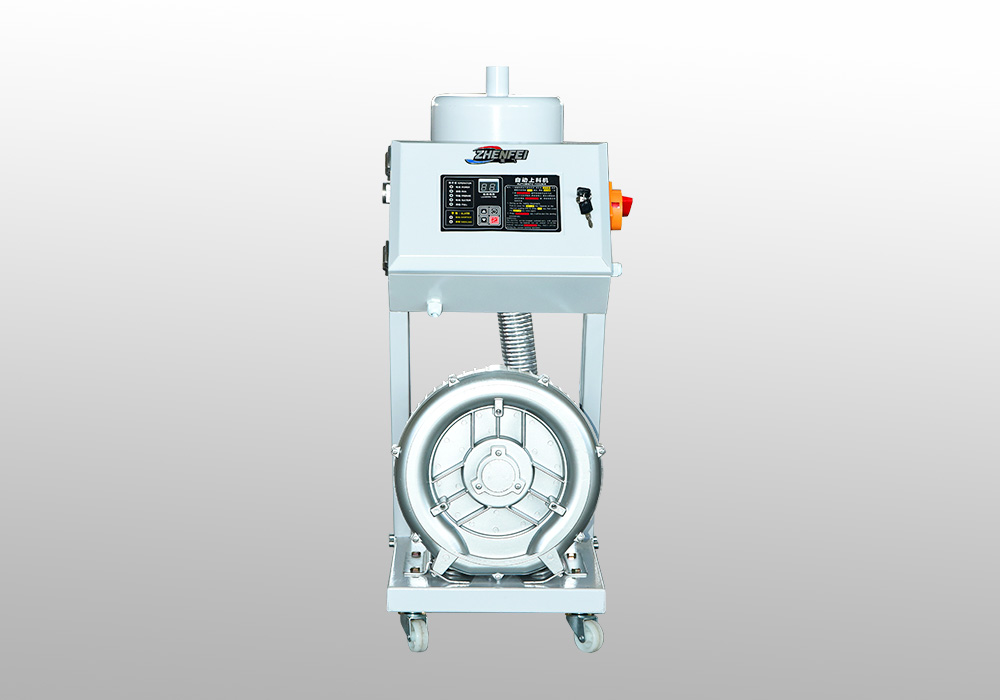

(a) Separate design of main unit and stocker to make the production environment safer and more convenient

(b) Independent filter unit for easy identification of residual materials

(c) Silent device to reduce running noise

(d) Stainless steel storage tank, light and durable and easy to clean

(e) Control box independent design, microcomputer automatic movement

(f) Motor automatic protection device

(g) Automatic short beep alarm notification

(h) Add dust removal device if required by customers