In the ever-evolving landscape of industrial automation, the

HAL Vacuum Autoloader emerges as a transformative pressure, showcasing remarkable talents in material handling. This advanced autoloading device has redefined the efficiency and precision of cloth transfer, seamlessly integrating into various manufacturing techniques to streamline operations and enhance general productiveness.

At the heart of the HAL Vacuum Autoloader's achievement lies its contemporary vacuum era. This innovative machine employs a complicated vacuum mechanism that permits the mild and particular coping with of a wide range of materials. Whether dealing with delicate additives or heavy-responsibility substances, the autoloader ensures a stable grip and smooth transfer, minimizing the threat of damage and maximizing production output.

What units the HAL Vacuum Autoloader aside is its ability to conform to diverse manufacturing environments simply. The gadget is designed to deal with extraordinary shapes, sizes, and weights of substances, providing a flexible answer for producers across diverse industries. Its intuitive interface permits operators to customise loading parameters, ensuring a tailor-made technique to each particular production requirement. This adaptability no longer only enhances operational flexibility but additionally contributes to a reduction in setup times, enabling producers to respond hastily to converting demands.

One of the standout functions of the HAL Vacuum Autoloader is its real-time tracking and feedback skills. Equipped with sensors and sensible control systems, the autoloader continuously assesses the popularity of substances for the duration of switch. This proactive technique permits the system to make real-time adjustments, ensuring a consistent and precise fabric go with the flow. The result is a big discount in errors and waste, contributing to cost financial savings and stepped forward ordinary best inside the manufacturing system.

The HAL Vacuum Autoloader doesn't just excel in functionality; it prioritizes person revel in as nicely. The interface is designed with simplicity and clarity in thoughts, allowing operators to have interaction seamlessly with the gadget. Intuitive controls and a user-friendly dashboard empower operators to monitor and manipulate material transfer resultseasily. This awareness on usability now not best reduces the gaining knowledge of curve for operators but also minimizes the chance of errors, contributing to a safer and greater efficient operating environment.

By using combining ultra-modern vacuum era with adaptability, actual-time tracking, and consumer-friendly layout. As production techniques keep to adapt, this

HAL Vacuum Autoloader stands as a beacon of innovation, reshaping the panorama of fabric coping with and setting new standards for performance and precision in business automation.

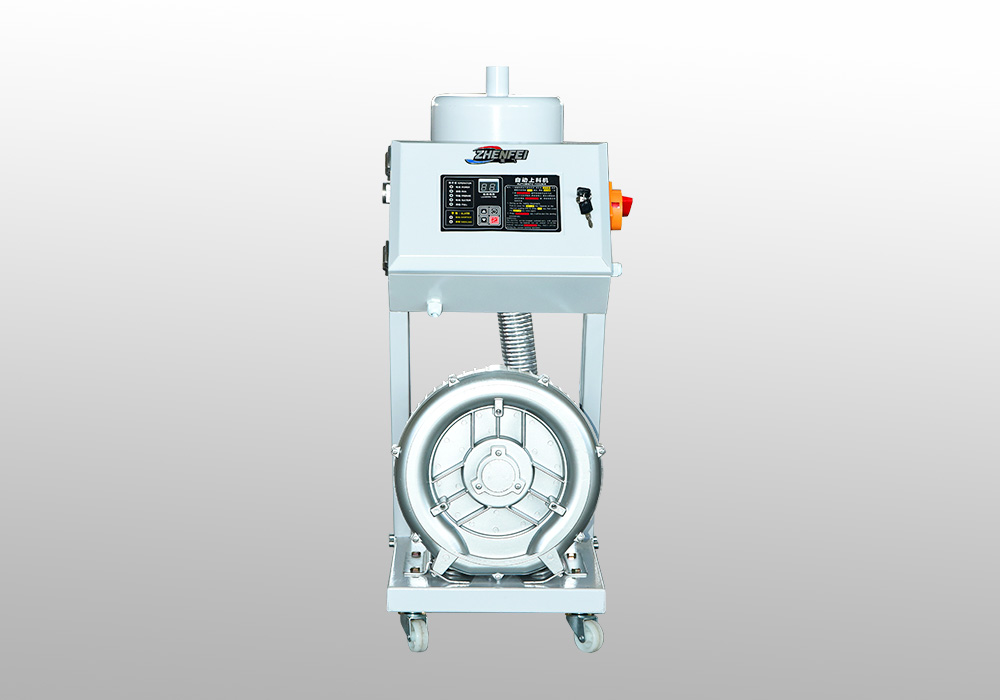

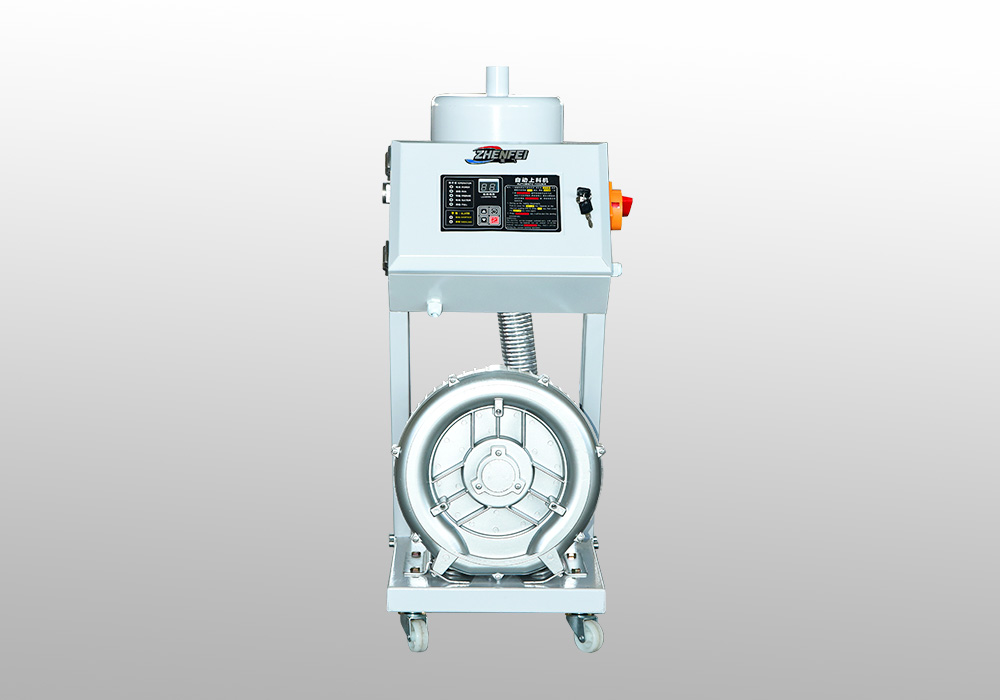

HAL VACUUM AUTOLOADER

HAL VACUUM AUTOLOADER

(a) Separate design of main unit and stocker to make the production environment safer and more convenient

(b) Independent filter unit for easy identification of residual materials

(c) Silent device to reduce running noise

(d) Stainless steel storage tank, light and durable and easy to clean