Date:Sep 08, 2025

| Feature | Hydraulic Injection Molding Machine | Electric Injection Molding Machine |

|---|---|---|

| Cost | Lower equipment cost | Higher initial investment |

| Torque & Pressure | High torque, suitable for large tonnage | Torque limited by motor, suitable for small to medium tonnage |

| Material Compatibility | Can handle high-viscosity and engineering plastics | May have limitations with high-viscosity materials |

| Precision & Repeatability | Moderate precision, affected by hydraulic oil temperature | High precision, high repeatability, minimal fluctuation |

| Energy Consumption | High energy consumption, continuous heating of hydraulic oil | Energy-saving, power only when needed, reduces electricity costs |

| Noise | Relatively high | Low noise |

| Maintenance | Complex hydraulic system, requires regular oil changes and maintenance | Easy maintenance, no hydraulic oil leakage issues |

Hydraulic Injection Molding Machine Disadvantages:

Electric Injection Molding Machine Disadvantages:

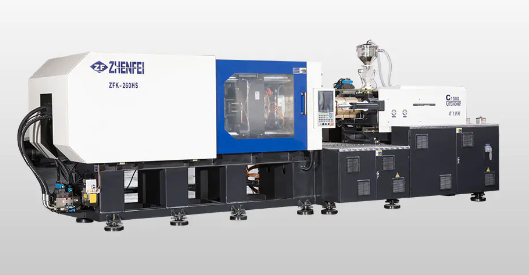

Hydraulic Injection Molding Machine:

Electric Injection Molding Machine: