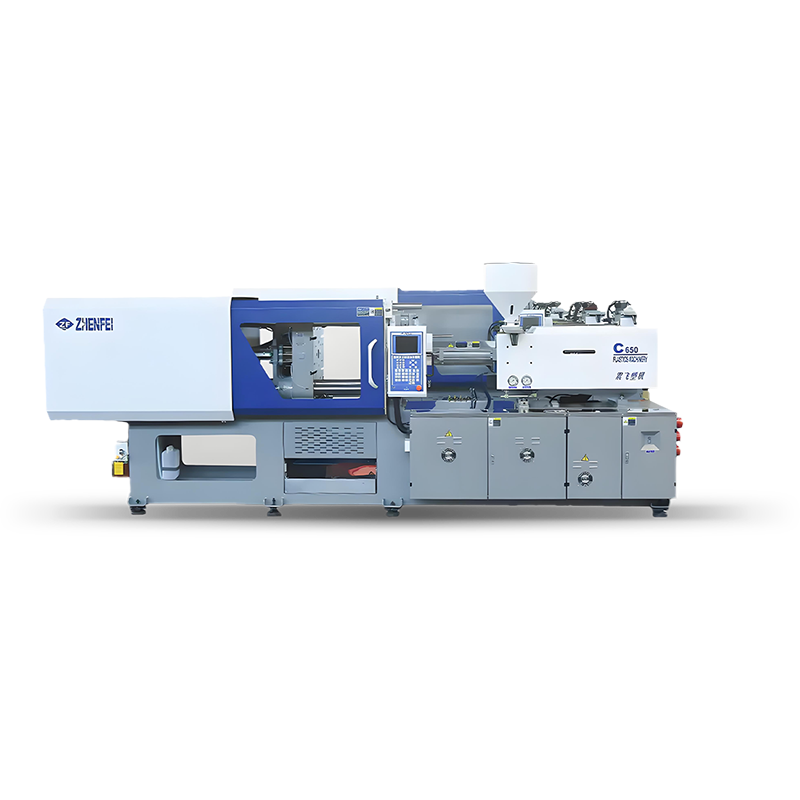

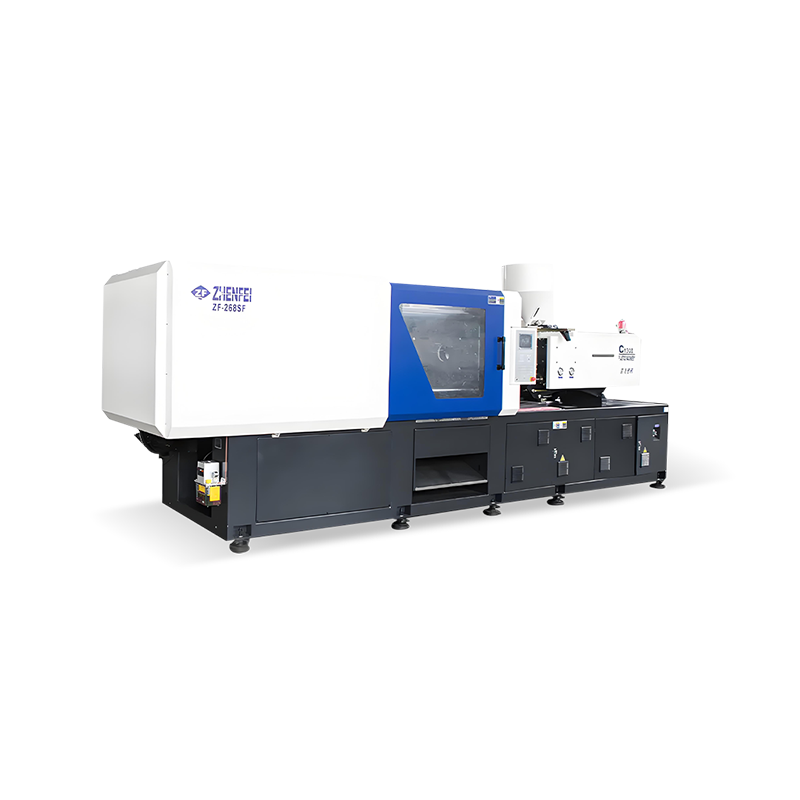

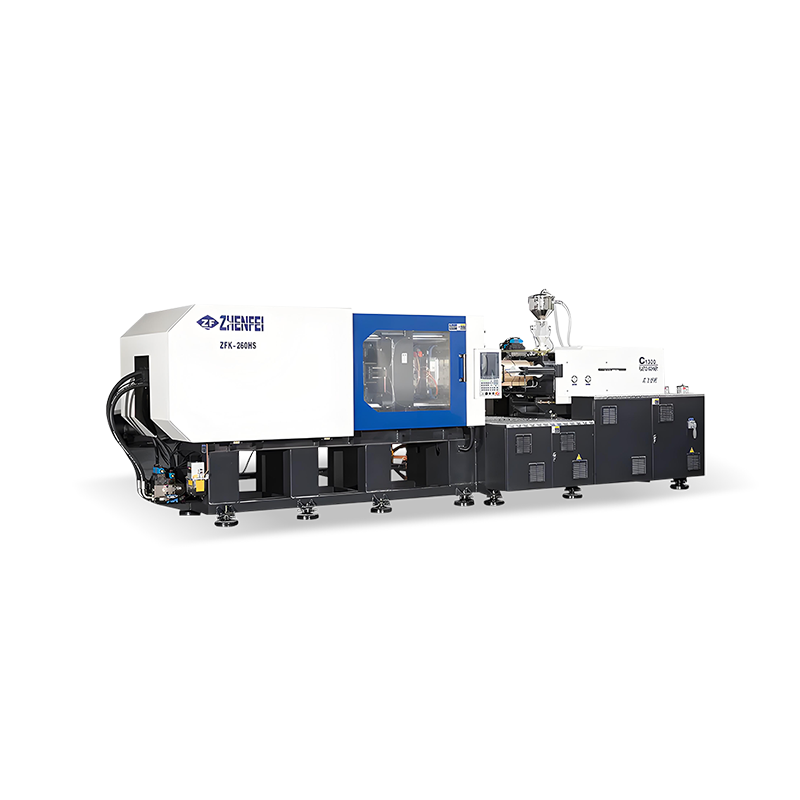

Injection molding has long been a cornerstone of modern manufacturing, providing the means to create a diverse range of plastic products efficiently and at scale. From intricate components used in consumer electronics to large parts for the automotive and medical industries, injection molding remains one of the most precise and cost-effective manufacturing methods. Ningbo Zhenfei Injection Molding Machine Manufacturing Co., Ltd., a leading player in the field, is known for its innovative ZF Series injection molding machines, which combine cutting-edge technology with reliable performance. With certifications like ISO9001-2008, CE, and UE, Ningbo Zhenfei has built a reputation for quality and consistency in the global market.

An injection molding machine (IMM) functions by injecting molten plastic into a mold cavity under high pressure, where it solidifies into a predetermined shape. The process includes several key stages: clamping, injection, cooling, and ejection. Ningbo Zhenfei’s ZF Series machines are designed for optimal performance at each of these stages, ensuring fast cycle times, minimal material waste, and high-quality parts.

1. What is an Injection Molding Machine?

An injection molding machine is a highly specialized piece of equipment designed for producing plastic components. It works by heating plastic pellets until they become molten and then injecting this molten material into a mold cavity under high pressure. Once the plastic cools and solidifies, the part is ejected from the mold. This method allows for mass production of plastic parts with consistent quality and high precision.

The process is composed of four primary stages:

| Stage |

Description |

| Clamping |

The mold is closed tightly to prevent any leakage during injection. Clamping force is applied based on the mold size and material used. |

| Injection |

Molten plastic is injected into the mold cavity under high pressure. The material fills the mold to take its shape. |

| Cooling |

After injection, the part is allowed to cool and solidify. The cooling time depends on the material and the part’s thickness. |

| Ejection |

Once the part is cooled, it is ejected from the mold, often using ejector pins or an automated system. |

Ningbo Zhenfei Injection Molding Machine Manufacturing Co., Ltd. has perfected the design of the ZF Series machines, optimizing each of these stages to ensure fast cycle times, energy efficiency, and high-quality output. These machines are known for their precision, which is critical for producing intricate designs and parts with tight tolerances.

Key benefits of Ningbo Zhenfei’s machines include:

- High-speed production capabilities

- Energy-saving designs

- Advanced temperature control systems

- Precision molding for complex parts

With the backing of ISO9001-2008 and CE/UE certifications, Ningbo Zhenfei ensures that every ZF Series machine meets rigorous international standards for performance and quality. Their focus on innovation and customer satisfaction makes them a trusted partner for manufacturers seeking top-tier injection molding technology.

2. Types of Plastic Molding Machines

While injection molding is the most widely used method, there are other types of plastic molding machines designed for specific applications. Each type has distinct advantages, depending on the materials, design, and production needs. Ningbo Zhenfei primarily specializes in injection molding machines but also understands the relevance of other molding processes to specific industries. Below are the main types of plastic molding machines:

| Molding Machine Type |

Description |

| Injection Molding Machines |

Used for injecting molten plastic into a mold under high pressure. Ideal for producing complex and high-precision parts at scale. |

| Blow Molding Machines |

Used to create hollow parts such as bottles and containers. The molten plastic is inflated inside a mold to form the part. |

| Compression Molding Machines |

Used for thermoset plastics and larger parts. The material is placed into a heated mold and then compressed into the desired shape. |

| Rotational Molding Machines |

Rotational molding creates large hollow products, such as tanks and playground equipment, by rotating the mold as it is heated. |

| Extrusion Molding Machines |

Used to produce continuous profiles like pipes, films, or sheets. The plastic is forced through a mold and cooled as it exits the machine. |

Each molding process offers unique advantages, and Ningbo Zhenfei’s focus is on providing highly customizable and versatile ZF Series injection molding machines that meet the needs of a wide range of industries, including automotive, medical, and consumer electronics.

For example, Ningbo Zhenfei injection molding machines are specifically designed to handle thermoplastics, thermosets, and a variety of other material types, giving manufacturers flexibility when selecting raw materials. The integration of energy-efficient technologies also makes Ningbo Zhenfei’s machines stand out in terms of operational costs.

3. The Benefits of Injection Molding in Manufacturing

Injection molding offers a host of benefits that make it the go-to method for producing high-quality, complex plastic parts at scale. The precision, speed, and versatility of injection molding machines—like those designed and manufactured by Ningbo Zhenfei Injection Molding Machine Manufacturing Co., Ltd.—play a significant role in driving the efficiency and profitability of modern manufacturing. Below are some of the primary benefits:

High-Speed Production

Injection molding machines are designed to produce large quantities of parts quickly. This is achieved through fast injection cycles, which allow manufacturers to produce thousands of parts per day. With Ningbo Zhenfei’s ZF Series machines, production speeds are optimized to ensure that manufacturers can meet high-volume demands without compromising on quality.

Precision and Consistency

Injection molding is one of the most precise manufacturing methods available. The tight control over injection pressure, material flow, and cooling times results in highly consistent parts with minimal variation in dimensions. This is especially critical for industries such as electronics or medical devices, where even a slight defect can render a part useless. Ningbo Zhenfei’s ZF Series machines excel in providing the high level of precision required for producing parts with tight tolerances.

Cost-Effectiveness for Large Volumes

Although the initial setup for injection molding, including mold design and machine installation, can be costly, the per-unit cost decreases significantly with high-volume production. Once the molds are in place, the cost to produce each part drops, making it a highly cost-effective method for mass production. Ningbo Zhenfei’s machines are designed for efficiency, with features that help to minimize material waste and maximize energy savings, ultimately lowering operational costs.

Material Efficiency and Flexibility

Injection molding is a material-efficient process, with minimal waste generated during production. The machines are designed to use precisely the amount of plastic required, and any excess can often be recycled back into the system. This not only helps to reduce material costs but also makes injection molding an environmentally friendly option.

Furthermore, Ningbo Zhenfei’s machines are compatible with a wide range of plastic materials, offering flexibility in choosing the right material for specific applications. Whether manufacturers need high-strength plastics for automotive parts or flexible polymers for consumer goods, Ningbo Zhenfei’s ZF Series can handle it all.

Design Flexibility

Injection molding allows manufacturers to create intricate designs with complex geometries, including parts with thin walls, fine details, and multi-component features. This design flexibility is invaluable for producing parts that are lightweight, durable, and cost-effective.

Sustainability and Environmental Impact

Due to its efficiency and precision, injection molding is often considered one of the more sustainable manufacturing methods. Ningbo Zhenfei integrates energy-saving technologies into its ZF Series machines, helping manufacturers reduce their carbon footprint. By optimizing energy use and minimizing waste, these machines not only reduce costs but also align with growing sustainability goals in manufacturing.

中文简体

中文简体 English

English Español

Español

中文简体

中文简体